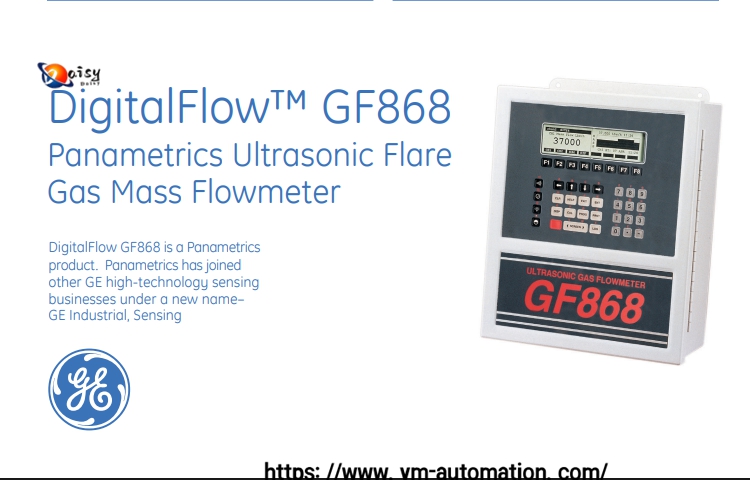

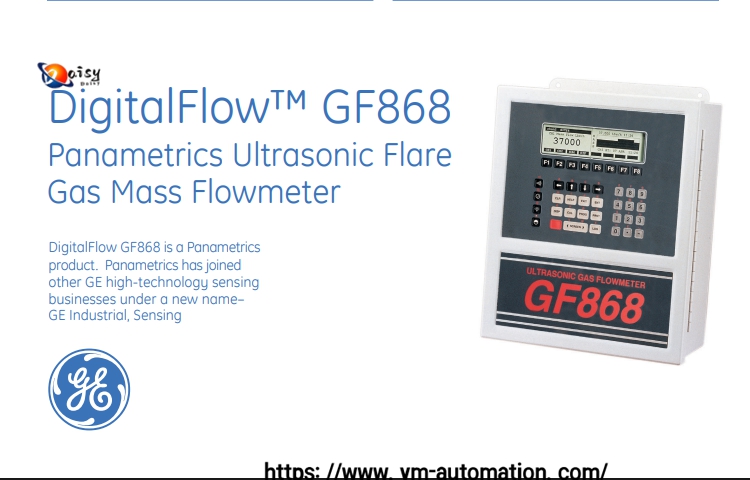

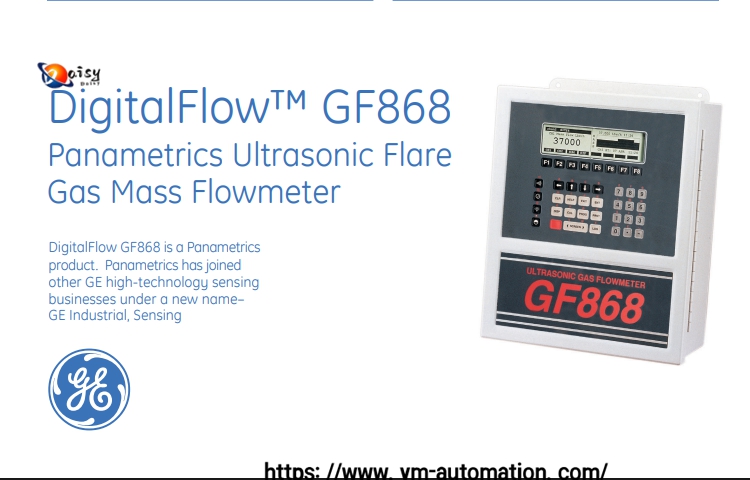

GE GF868-1-1-1-2-1-0 -1-4-0-0-0-RPT Ultrasonic Gas Flow Meter Parameters:

- Product Type

- Application Scenarios: Industrial gas flow measurement (e.g., natural gas,

compressed air, industrial waste gas, etc.) - Measurement Principle: Time-difference ultrasonic measurement technology

- Certifications: May comply with explosion-proof certifications such as ATEX and IECEx

(depending on configuration)

- Core Parameters

Measurement Performance

- Flow Velocity Range: ±0.03~85 m/s (bidirectional flow measurement)

- Accuracy: ±1.0%~2.0% (depending on the number of sound channels and gas type)

- Repeatability: ±0.2%

- Turn-Down Ratio: ≥2750:1

- Response Time: Typically <100ms

Physical Parameters

- Diameter Range: DN15~DN6000 (depending on sensor type)

- Process Connection: Flange, threaded, or clamp-type (determined by the 3rd digit of the configuration code)

- Material: Sensor housing is stainless steel 316L; pipeline material can be carbon steel, stainless steel, etc.

- Protection Class: IP65/67 (depending on housing configuration)

Operating Conditions

- Medium temperature: -196°C~+260°C (depending on sensor type)

- Ambient temperature: -40°C~+85°C (depending on transmitter configuration)

- Temperature Range:

- Pressure Range: Up to 40MPa (depending on sensor and process connection)

Output and Communication

- Analog Output: 4~20mA (up to 4 channels, isolated)

- Digital Interface: RS485/Modbus RTU, HART, Profibus DP, FOUNDATION Fieldbus, etc.

- Protocols: Supports MID, AGA-9, ISO 17089, etc.

Power Supply

- Supply Voltage: 100~240VAC or 24VDC

- Power Consumption: <20W

- Configuration Code Interpretation (Example)

- GF868-1-1-1-2-1-0 -1-4-0-0-0-RPT

-

- 1st digit: Application scenario (1=standard gas)

- 2nd digit: Sensor type (1=insertion type)

- 3rd digit: Process connection (1=flange)

- 4th digit: Number of sound channels (2=dual-channel)

- 5th digit: Output option (1=basic analog output)

- 6th digit: Special function (0=none)

- 7th digit: Communication protocol (1=Modbus RTU)

- 8th digit: Certification level (4=non-explosion-proof)

- 9th to 11th digits: Custom options

- 12th digit: Accessory (RPT=remote display terminal)

- Application Fields

- Natural gas trade measurement

- Industrial gas process control

- Energy management and carbon emission monitoring

- Compressed air system efficiency optimization