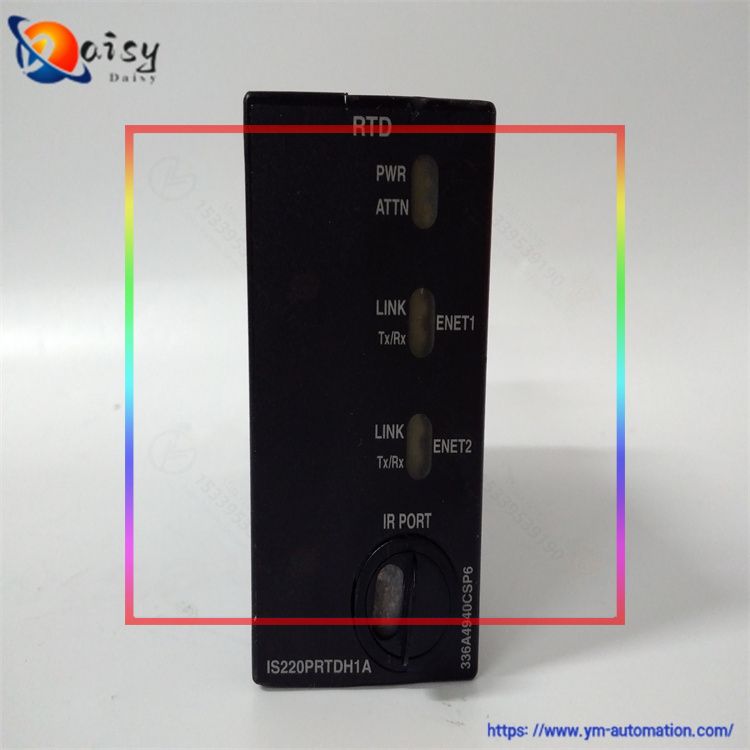

Functional Description:

IS210BAPAH1A is an analog processor module manufactured and designed by General Electric (GE). It belongs to the Mark VI series used in GE Speedtronic gas turbine control systems. The analog processor module plays a crucial role in managing and regulating analog signals related to the operation of gas turbines. Gas turbine control systems need to accurately monitor and adjust various parameters to ensure optimal performance, efficiency, and safety. The analog processor module helps process continuous analog signals generated by sensors and instruments throughout the gas turbine system. The specific functions of the analog processor module in the gas turbine control system are as follows:

Sensor Interface: Gas turbines are equipped with numerous sensors for measuring parameters such as temperature, pressure, speed, and fuel flow. The analog processor module interfaces with these sensors to receive analog signals representing these physical quantities.

Signal Conditioning: Analog signals from sensors may require conditioning before being used for control purposes. The analog processor module contains components such as amplifiers, filters, and converters to properly condition and scale these signals.

Control Signal Generation: The processed analog signals are then used to generate control signals that regulate various aspects of gas turbine operation. This may involve adjusting fuel flow, controlling the combustion process, or managing turbine speed.

Feedback Control: Gas turbine control systems typically employ feedback loops to continuously monitor turbine performance and make real-time adjustments. The analog processor module can process feedback signals to maintain stable and efficient operation.

Fault Detection and Diagnosis: The analog processor can be programmed to analyze analog signals for anomalies that may indicate system faults or abnormalities. Early detection of issues is crucial for preventing damage and ensuring the reliability of the turbine.

Compatibility with Digital Systems: While analog processing is vital, modern gas turbine control systems usually integrate both analog and digital components. The analog processor module can interface with digital controllers and communication systems to exchange information and implement coordinated control strategies.