The GE IC660HHM501 is a handheld monitor under GE Fanuc. Below is an introduction to its parameters, application scenarios, and operating principle:

1. Parameters

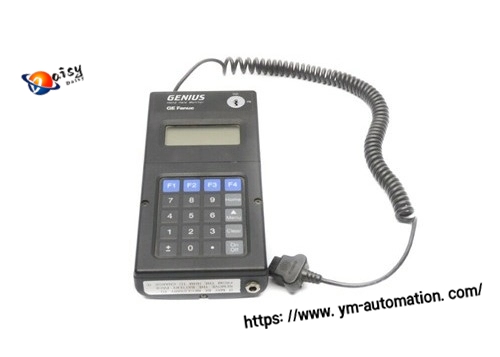

Dimensions & Weight:

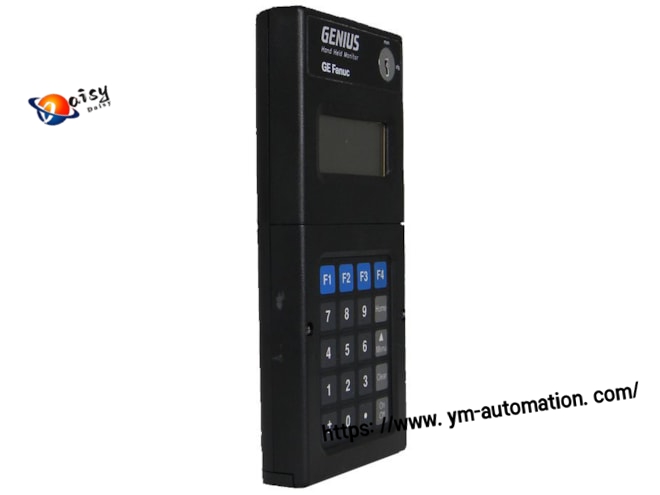

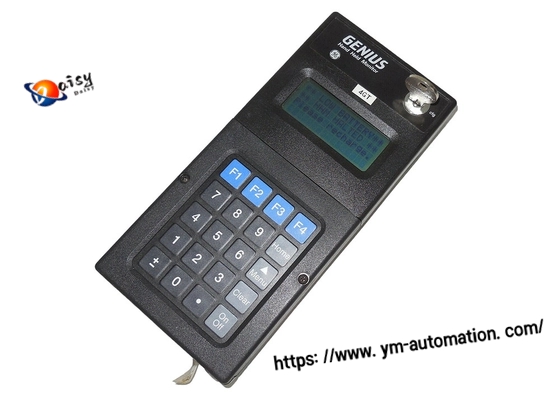

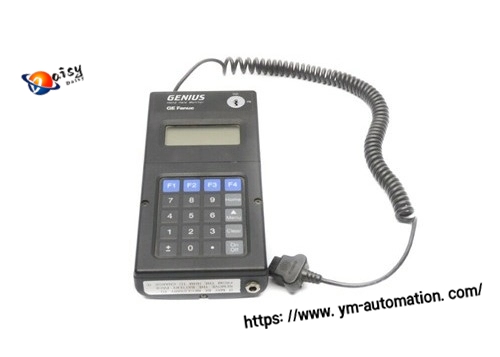

The monitor itself weighs 1.6 lbs (pounds) with dimensions of 8.00” × 3.75” × 1.25” (inches).

When stored in its protective case, it weighs 1.8 lbs with dimensions of 10.85” × 4.30” × 2.25”.

Power Supply:

Compatible with 115VAC or 230VAC power sources.

The battery charger requires an AC power supply of 115/230VAC (±15%), 47–63Hz.

A battery pack must be installed even when using AC power; a full battery charge takes approximately 6 hours.

Operating Environment:

Operating temperature range: 0–60°C (32–140°F).

Storage temperature range: -40–70°C (-40–158°F).

Humidity range (non-condensing): 5%–95%.

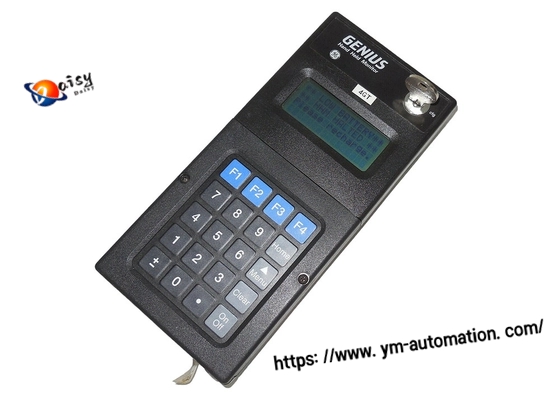

Display & Input:

Equipped with a 4-line LCD display, 16 characters per line.

Supports display in 4 languages: English, Spanish, French, and Italian.

Features a 20-key sealed membrane keypad, plus a key switch to restrict access to certain functional operations.

2. Application Scenarios

Industrial Automation:

Widely used in industries such as manufacturing, packaging, food processing, automotive manufacturing, electronics, machinery, petrochemicals, chemicals, and pharmaceuticals. It enables on-site monitoring, diagnosis, and troubleshooting of industrial automation equipment.

Process Control:

Applied to the monitoring and maintenance of industrial production lines, as well as troubleshooting and calibration of automation equipment. It can real-time monitor and control various parameters during the production process.

Power Systems:

Usable for monitoring and controlling power systems, helping staff stay updated on the operating status of power systems and perform relevant operations and maintenance.

3. Operating Principle

As an interface operation device for the Genius I/O and communication system, the IC660HHM501 can connect to the Genius bus. It operates independently of PLCs (Programmable Logic Controllers) or computers, communicating directly with I/O modules and supporting forcing of discrete and analog I/O signals.

Via its display screen, it can show I/O data of the Genius bus and all its connected devices, CPU memory data, global data addresses, bus scan time, diagnostic information, and device descriptions. Operators can use this information to set up, monitor, and configure the system, thereby realizing on-site operation and maintenance of industrial automation systems.