Brand:Emerson

Product ID:

Place of Origin:

Warranty: 365 days

Goods status: new/used

Mail: 3598571032@qq.com

Phone/Wechat/Whatsapp:+86 15339539190

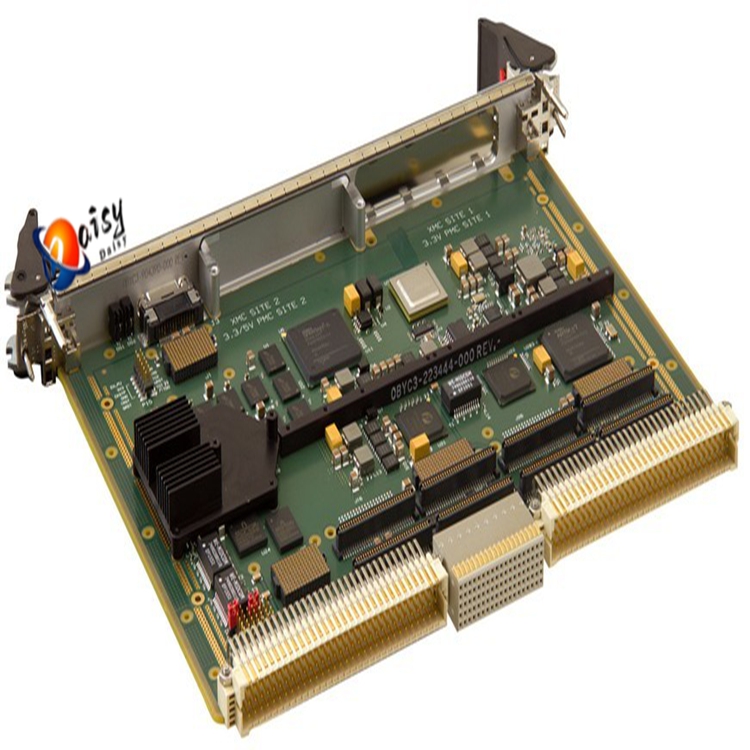

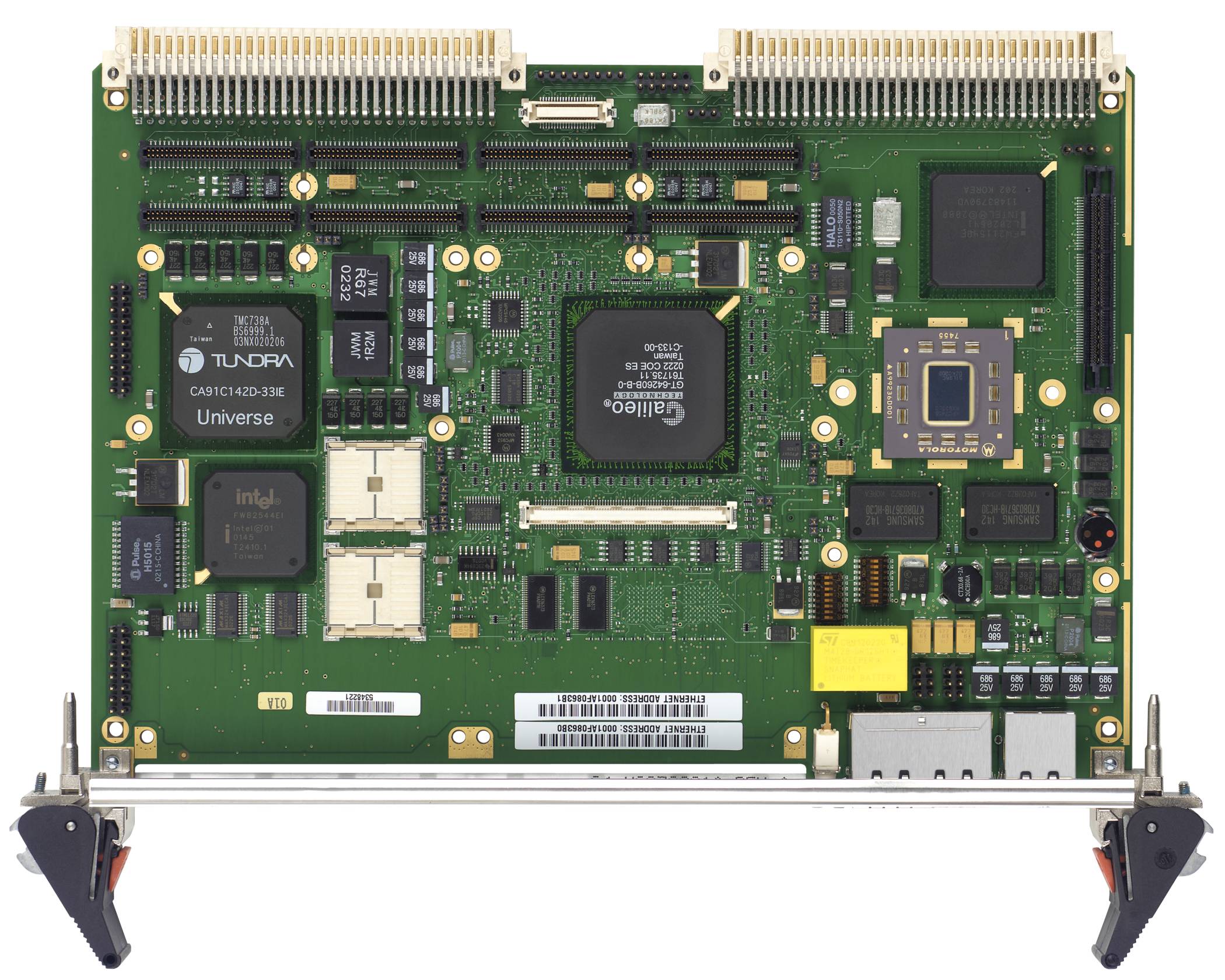

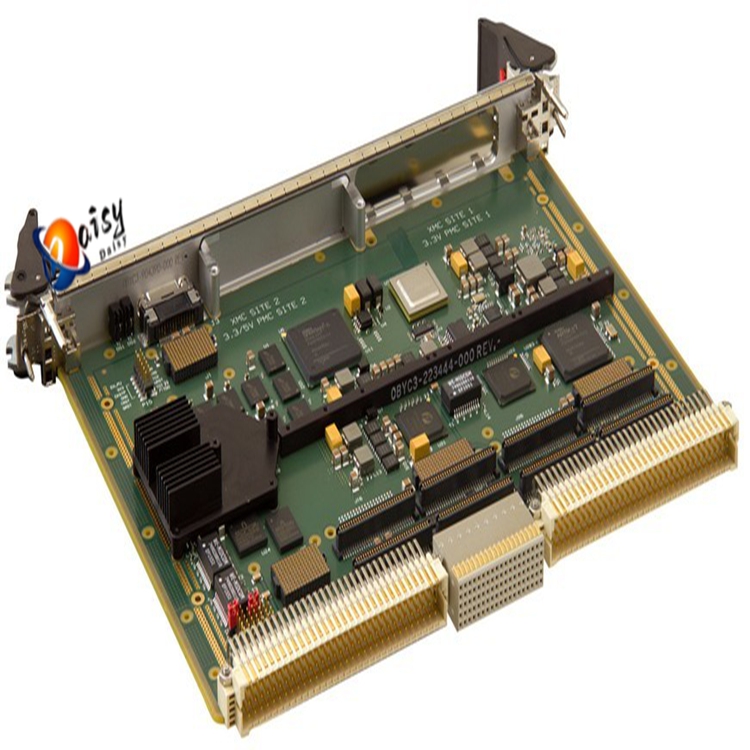

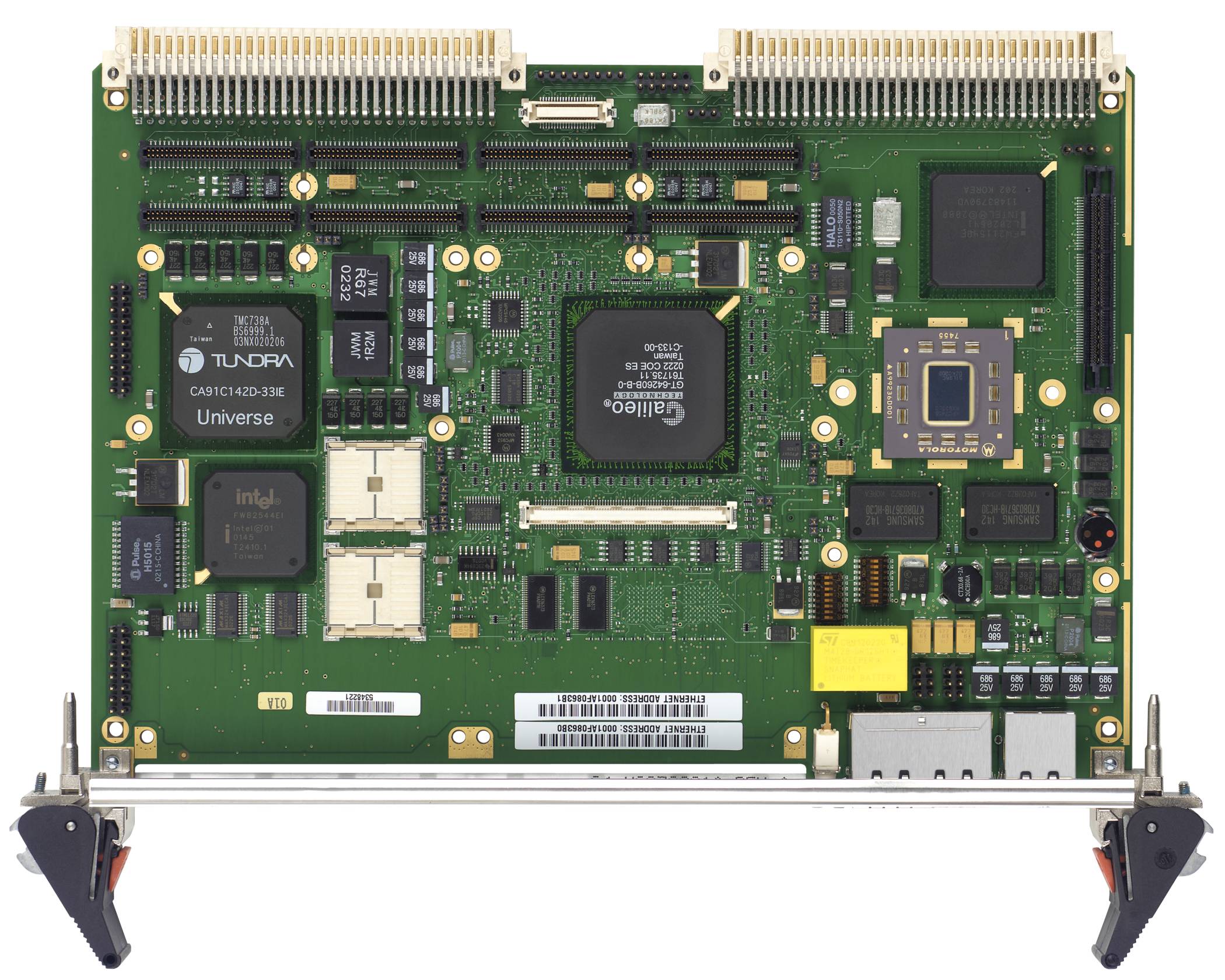

EMERSON TPMC917 is a high-performance controller specifically designed for industrial automation control. It is often used in conjunction with the MVME5500 (a classic single-board computer from the Motorola/Motorola Embedded Systems series, which Emerson frequently integrates in the field of industrial control). This combination is widely applied in industrial scenarios that have strict requirements for reliability and real-time performance. Below is a detailed explanation of the core information for both devices:

I. Core Parameters (TPMC917 + MVME5500)

Since the TPMC917 and MVME5500 are often used as an integrated system, their parameters need to be comprehensively explained based on the core configurations of both. The MVME5500, as the core computing module, determines the basic computing capability of the system.

1. Core Parameters of TPMC917 (Controller)

Processor (CPU): Equipped with a high-performance industrial-grade processor (typically of PowerPC architecture, such as the Motorola MPC7457) with a clock speed of up to 1.0GHz. It supports hardware floating-point operations to ensure the real-time operation of complex control algorithms.

Memory and Storage:

Memory: Standard configuration includes 512MB DDR SDRAM (expandable up to 1GB), with ECC error checking to enhance data reliability.

Storage: Integrates 512MB of flash memory (for storing system programs and configuration files) and supports CompactFlash card expansion.

Communication Interfaces:

Industrial Bus: Supports mainstream industrial protocols such as Profibus-DP, Modbus TCP, EtherNet/IP, and Foundation Fieldbus (FF).

General-Purpose Interfaces: Includes 2 Gigabit Ethernet ports, 4 RS-232/485 serial ports, and a USB 2.0 interface (for configuration and debugging).

Power Supply and Power Consumption:

Input power supply is 24VDC (industrial standard), supporting a wide voltage range (18-36VDC) with reverse connection protection and overvoltage protection.

Typical power consumption is ≤25W (under full-load operation).

Operating Environment:

Operating temperature range: -40℃~70℃ (industrial wide-temperature grade).

Humidity range: 5%~95% (non-condensing).

Protection rating: IP20 (when panel-mounted, a cabinet is required to achieve IP54 or higher).

Anti-interference: Complies with the EN 61000-6-2 standard (for anti-electromagnetic interference in industrial environments).

Software Support: Supports Emerson DeltaV control system software (for configuration, programming, and monitoring) and is compatible with the IEC 61131-3 standard (supporting programming methods such as ladder diagram, function block diagram, and structured text).

2. Core Parameters of MVME5500 (Single-Board Computer)

Processor (CPU): Standard configuration includes a Motorola MPC7457 PowerPC processor (with a clock speed of 800MHz/1.0GHz). Higher-performance versions are optional for some models, featuring strong anti-interference capabilities.

Memory and Storage:

Memory: 512MB DDR SDRAM (with ECC checking), expandable up to 1GB at maximum.

Storage: Includes 256MB of flash memory + an optional 2.5-inch hard disk/solid-state drive, supporting industrial-grade storage media (temperature-resistant and vibration-resistant).

Communication and Expansion Interfaces:

Supports the VMEbus (an industrial standard backplane bus for connecting I/O modules and communication modules).

Communication interfaces include 1 Gigabit Ethernet port and 2 serial ports. Profibus/FF and other industrial bus interfaces can be added via expansion cards.

Power Supply and Power Consumption:

Input power supply is 5VDC/12VDC (powered by the TPMC917 or system backplane).

Typical power consumption is ≤15W (when operating independently).

Operating Environment:

Operating temperature range: -40℃~70℃.

Humidity range: 5%~95% (non-condensing).

Shock resistance: Complies with the MIL-STD-810G standard (resistant to impact and vibration, suitable for harsh industrial on-site environments).

Software Support: Supports the VxWorks real-time operating system (RTOS, an industrial-grade real-time system with a response time of ≤1ms) and Linux system. It can run Emerson control algorithm libraries and drivers.

II. Operating Principles

The TPMC917 serves as the "control core" of the system, while the MVME5500 acts as the "computing and expansion core". The two work together via the VMEbus or internal interfaces, forming a closed-loop control logic of "data collection - operation processing - control output - status feedback". The specific principles are as follows:

III. Application Scenarios

The system composed of the TPMC917 and MVME5500 is characterized by strong real-time performance, excellent anti-interference capability, and wide compatibility. It is mainly applied in industrial fields that have extremely high requirements for control accuracy and system stability:

1. Oil, Chemical, and Natural Gas Industry

Application Scenarios: "Process control" in large refineries, ethylene plants, and natural gas processing stations (such as reactor temperature/pressure control, pipeline flow regulation, and catalyst injection volume control).

Core Requirement Matching: Supports Foundation Fieldbus (FF, the mainstream bus in the petrochemical industry). Its wide-temperature design adapts to the high-temperature and high-corrosion on-site environment of refineries. The dual-machine hot backup ensures continuous production (avoiding production losses caused by equipment failures).

2. Power Industry (Thermal Power/Nuclear Power)

Application Scenarios: Boiler water level control and steam turbine speed regulation in thermal power plants, auxiliary systems in nuclear power plants (such as coolant circulation control), and data collection and grid-connection control of junction boxes in new energy power stations (such as large-scale photovoltaic power stations and wind farms).

Core Requirement Matching: It has strong anti-electromagnetic interference capability (adapting to the electromagnetic environment of high-voltage equipment in power plants) and fast real-time response speed (the steam turbine speed control requires a response time of ≤50ms). It complies with the "high reliability" standards of the power industry (e.g., compatible with the IEC 61850 power communication standard).

3. Chemical and Pharmaceutical Industry

Application Scenarios: Batch production processes in the chemical industry (such as polymerization reaction control) and GMP-compliant production in the pharmaceutical industry (such as precise temperature control for drug synthesis and environmental parameter monitoring in clean workshops).

Core Requirement Matching: Supports Modbus TCP/EtherNet/IP, facilitating connection with upper computers (e.g., MES production execution systems) to realize production data traceability. Its wide-temperature design adapts to the environmental differences between clean workshops in pharmaceutical factories and chemical reaction areas.

4. Metallurgy and Non-Ferrous Metals Industry

Application Scenarios: Temperature control of blast furnace hot stoves in iron and steel plants, liquid level regulation of continuous casting machine crystallizers, and electrode current control in the smelting process of non-ferrous metals (such as aluminum and copper).

Core Requirement Matching: It has strong resistance to vibration and impact (adapting to the mechanical vibration environment of metallurgical workshops), supports Profibus-DP (connecting to on-site frequency converters and sensors), and can realize coordinated control of multiple devices (such as the linkage of blast furnaces, hot stoves, and rolling mills).

5. Large-Scale Industrial Equipment (Heavy Machinery/Ships)

Application Scenarios: Hydraulic system control of large mining excavators, ship power systems (such as main engine speed regulation and steering gear control), and lifting/luffing control of port cranes.

Core Requirement Matching: It has a wide-voltage power supply (adapting to the unstable power supply in ships/mines), is resistant to harsh environments (high temperature, high humidity, and dust), and its real-time control ensures the operational accuracy of equipment (e.g., the positioning error of cranes is ≤5mm).

+86 15339539190