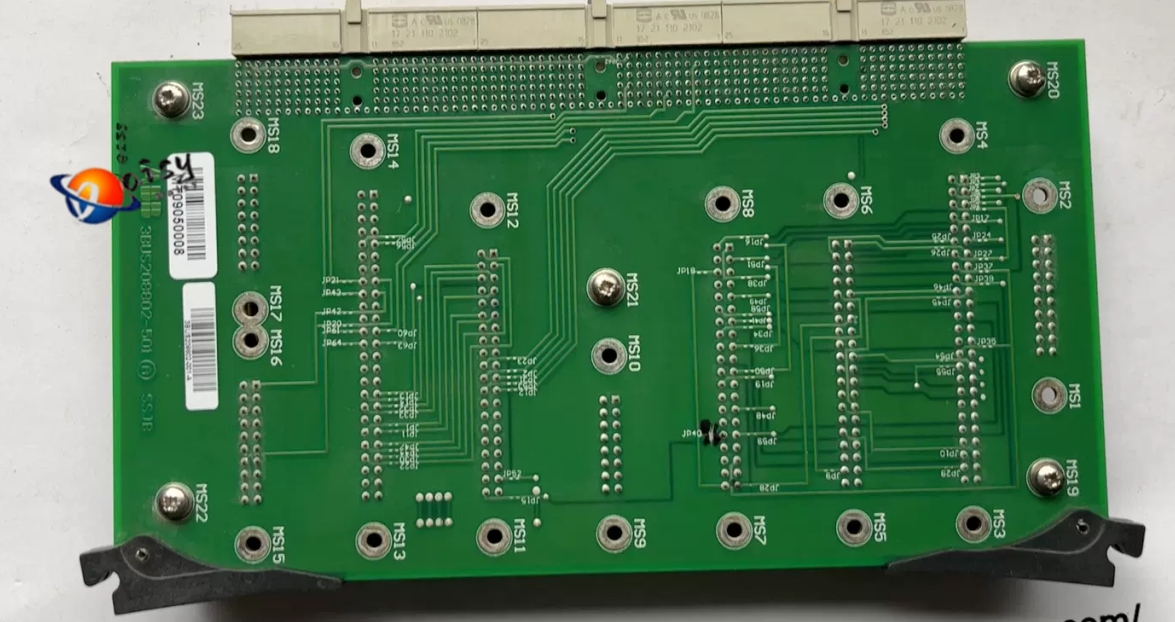

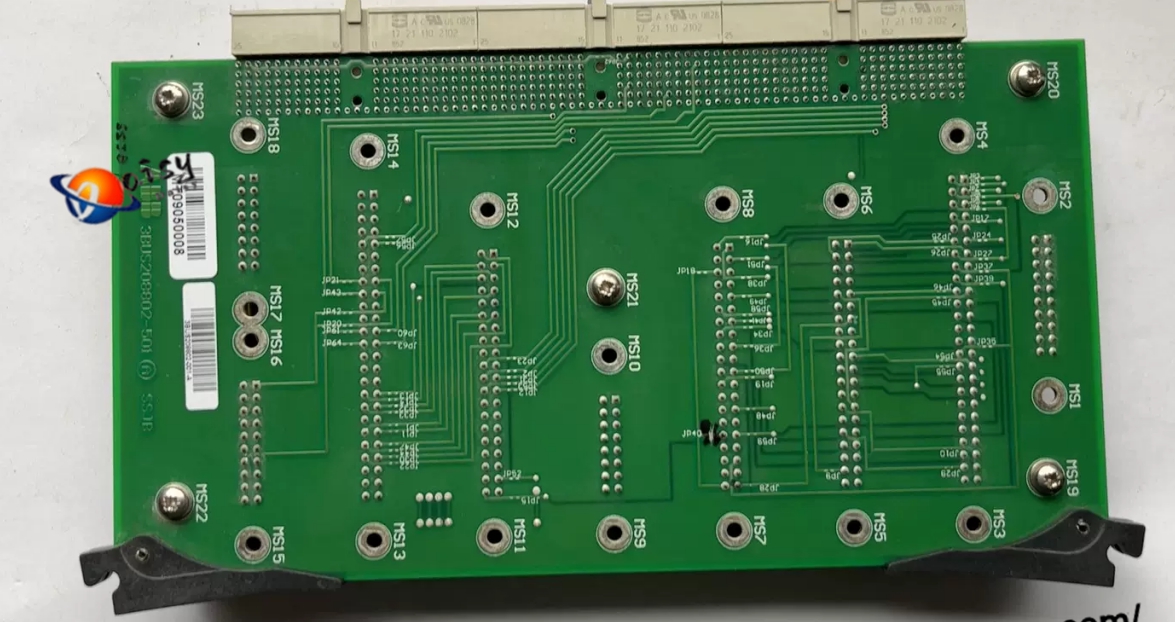

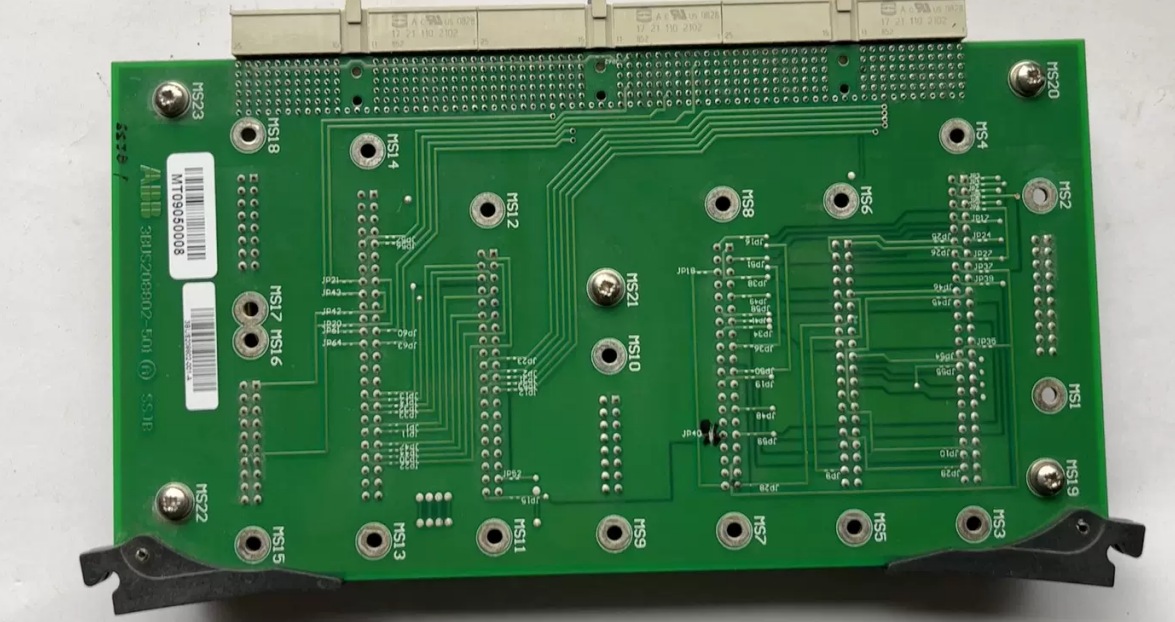

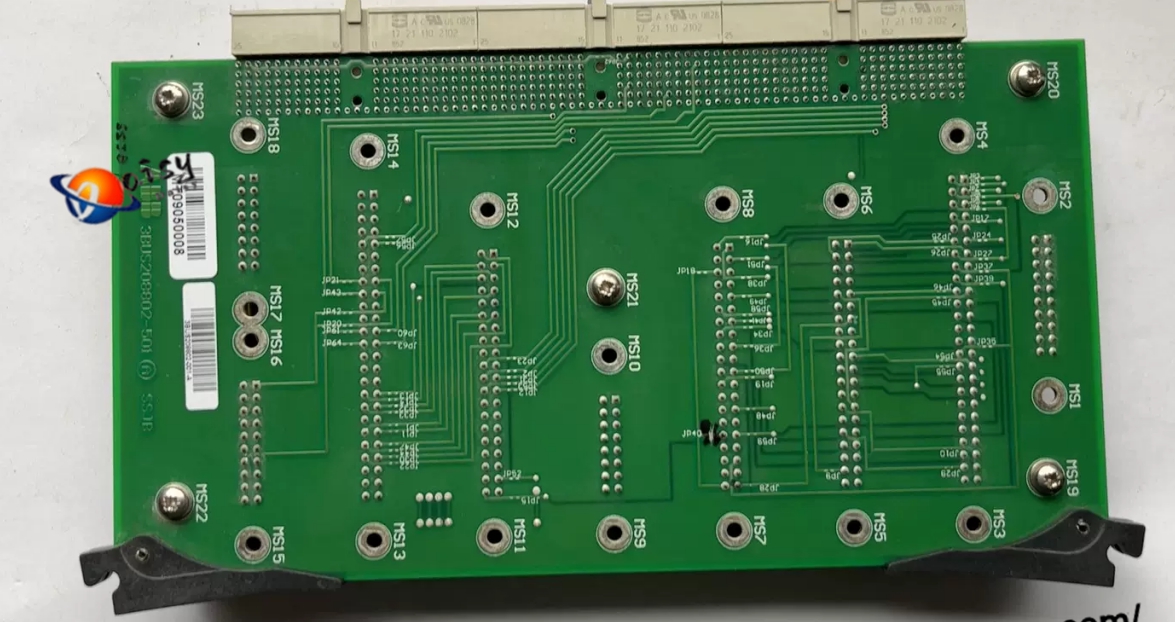

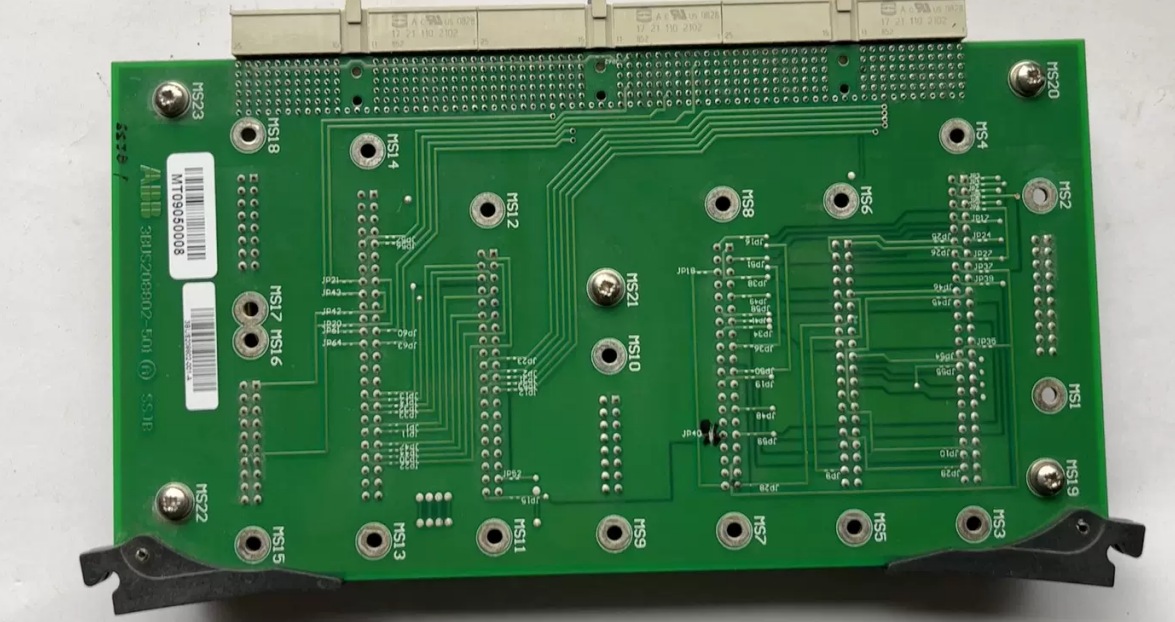

Summary of Core Information for ABB 3BUS208802-002

1. Product Definition

The ABB 3BUS208802-002 is a key functional component in industrial automation and control systems. Its core role is to work in collaboration with digital expansion driver cards, effectively enhancing the control accuracy and long-term operational stability of the system. This component has dual attributes: it is both a certified PLC (Programmable Logic Controller) module and a member of the DCS (Distributed Control System) module series. It can flexibly adapt to two mainstream control systems (PLC and DCS) and meet application requirements across multiple scenarios.

2. Key Parameters (Including Original Data Sheet Information)

(1) Electrical Parameters

Operating Voltage: Supports adaptation to multiple voltage environments, with a standard application specification of 220V. It is compatible with most standard power supply systems in industrial sites and can be connected without additional modifications.

Output Frequency: Up to 60KHZ, featuring high-speed data transmission and control signal processing capabilities. It can meet the needs of precision control scenarios with high signal response requirements (e.g., high-speed motor drive, real-time parameter adjustment).

(2) Basic Product Attributes

Origin and Quality: Originally produced in the United States, the manufacturing process adheres to ABB’s strict international production standards. Core components and processes undergo multiple rounds of testing to ensure reliable product quality.

Import Attribute: As an original imported product, its technical specifications and performance indicators comply with international general standards for industrial equipment, integrating ABB’s advanced technologies in the field of automation.

Customization and Maintenance: Adopts a standardized production model and does not support personalized custom processing. The product has strong consistency and component interchangeability, making it easier to replace parts during later maintenance and reducing operation and maintenance costs.

Basic Identification: Brand: ABB; Model: 3BUS208802-002; Material code corresponds to "PLC Module, DCS Module", facilitating inventory management and material traceability.

(3) Certification and Series

Product Certification: Has passed PLC module industry certification, complying with safety, performance, and compatibility standards for industrial control equipment. It is qualified for wide application in various industrial scenarios.

Affiliated Series: Belongs to the DCS module series. Its design is adapted to the structural characteristics of distributed control systems and can be seamlessly connected with other modules of the DCS system (e.g., signal acquisition modules, communication modules).

3. Application Scenarios

(1) Industrial Automation Production Lines

Mainly used for precise control of motor drives, fans, and pump equipment:

In automobile manufacturing production lines, it can control the start-stop and speed of conveyor motors and assembly motors, ensuring the coordinated operation of equipment in all processes and improving the stability of production cycles.

In chemical material transportation links, it can stably control the operating parameters (e.g., speed, output pressure) of material transfer pumps, avoiding deviations in material delivery volume caused by pump fluctuations and ensuring the consistency of production processes.

(2) Building Automation Systems

Focuses on the intelligent regulation of HVAC (Heating, Ventilation, and Air Conditioning) equipment in buildings:

Suitable for scenarios such as large office buildings and commercial complexes. It can automatically adjust the operating status of air conditioning units and fresh air fans based on real-time indoor parameters (e.g., temperature, humidity, personnel density). While meeting indoor comfort needs, it optimizes energy consumption (e.g., automatic frequency reduction during off-peak hours) to balance energy conservation and user experience.

(3) Process Control Industry

Used for parameter monitoring and regulation in continuous production processes:

Chemical Industry: Real-time monitoring of key parameters (e.g., temperature, pressure) of reaction kettles. When parameters deviate from preset thresholds, it automatically adjusts the operation of heating/cooling devices and stirring motors to ensure chemical reactions proceed safely and efficiently.

Metallurgical Industry: Used for auxiliary control in the blast furnace ironmaking process. It monitors parameters such as the speed of blast furnace air supply fans and the pressure of cooling water pumps, and adjusts the operating status of equipment in a timely manner to avoid production interruptions or safety risks caused by abnormal parameters.

4. Operating Principle

The ABB 3BUS208802-002 realizes its functions through a closed-loop logic of "collaborative access - signal processing - control output - status feedback", with the specific process as follows:

Collaborative Work: As an intermediate connecting component in the system, it first establishes a stable connection with peripheral equipment (e.g., digital expansion driver cards), then integrates into the PLC or DCS control system as a whole to form a complete control link.

Signal Processing: Receives command signals issued by the control system (e.g., "motor start", "adjust speed to 1500rpm"). Through its internally integrated circuit modules, it parses, amplifies, and performs logical operations on the signals, converting the commands into electrical signals recognizable by the actuators.

Control Output: Precisely transmits the processed signals to actuators (e.g., motors, valves, pumps), driving the actuators to perform corresponding actions in accordance with the commands and achieving precise control of the equipment.

Status Feedback: During operation, it real-time collects the operating status data of the actuators (e.g., motor operating current, speed, pump outlet pressure) and transmits the feedback signals back to the control system. The control system judges whether the equipment is operating normally based on the feedback data, and issues correction commands in a timely manner if deviations occur, forming closed-loop control to ensure the stable and reliable operation of the entire system.