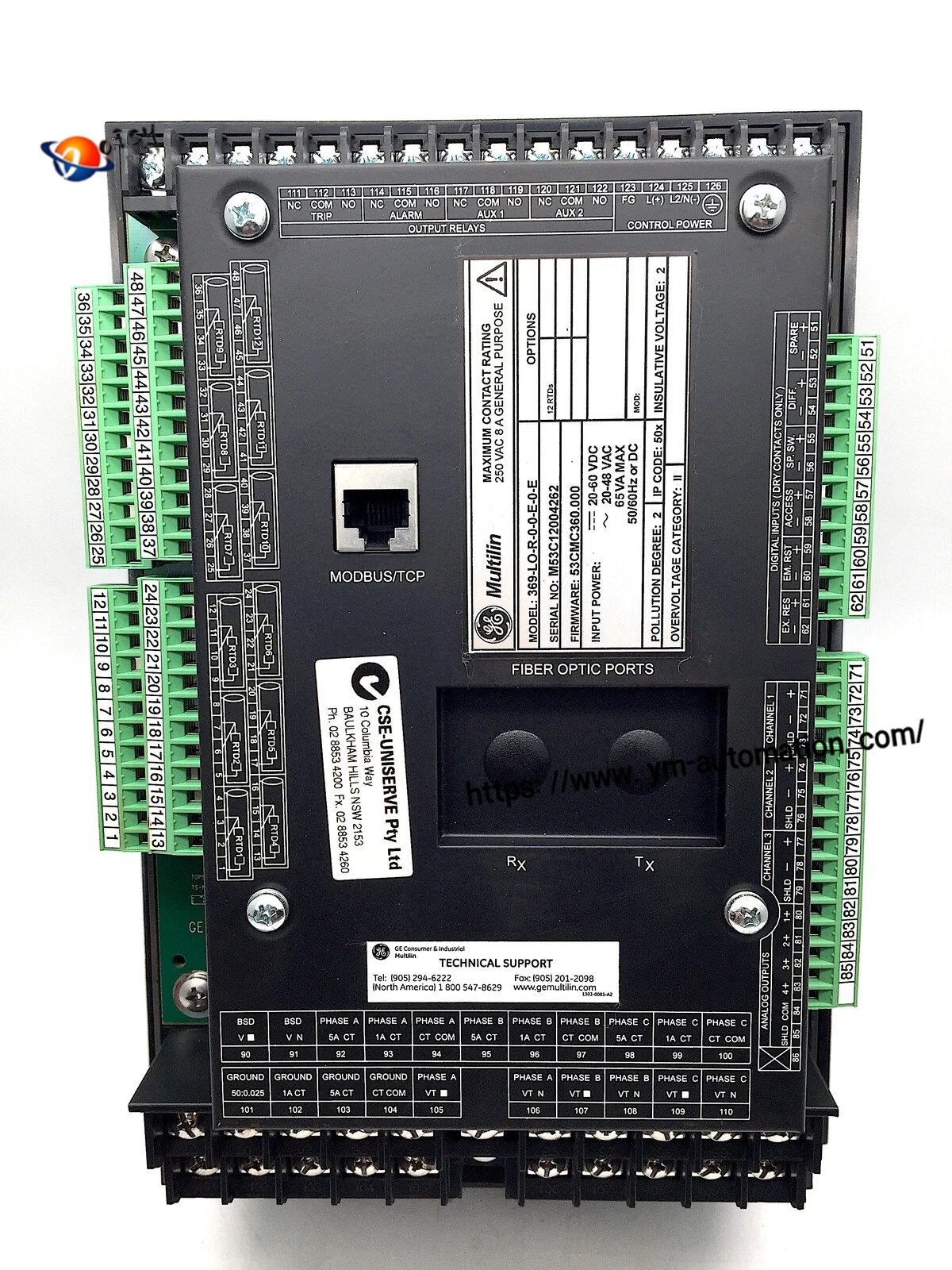

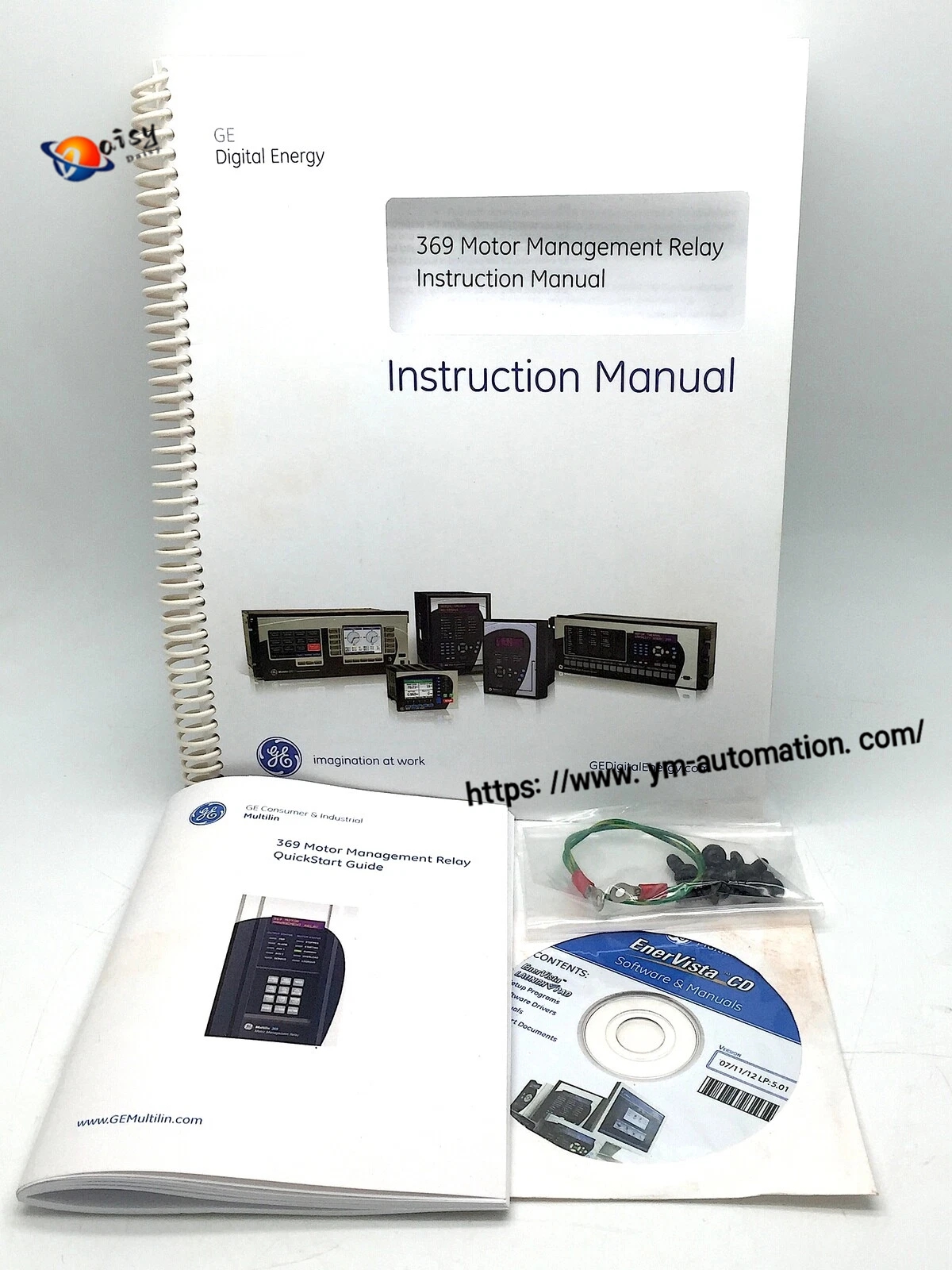

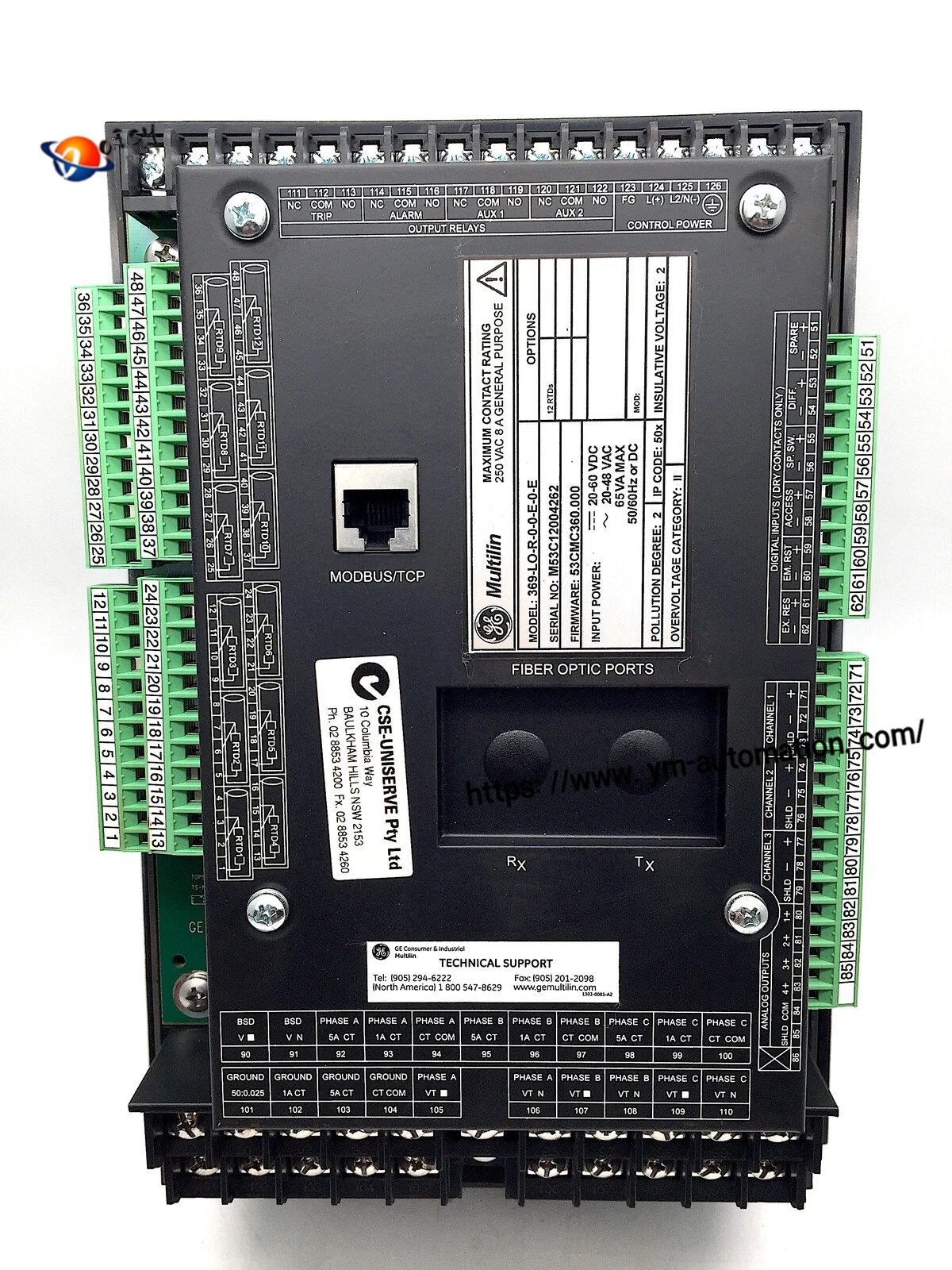

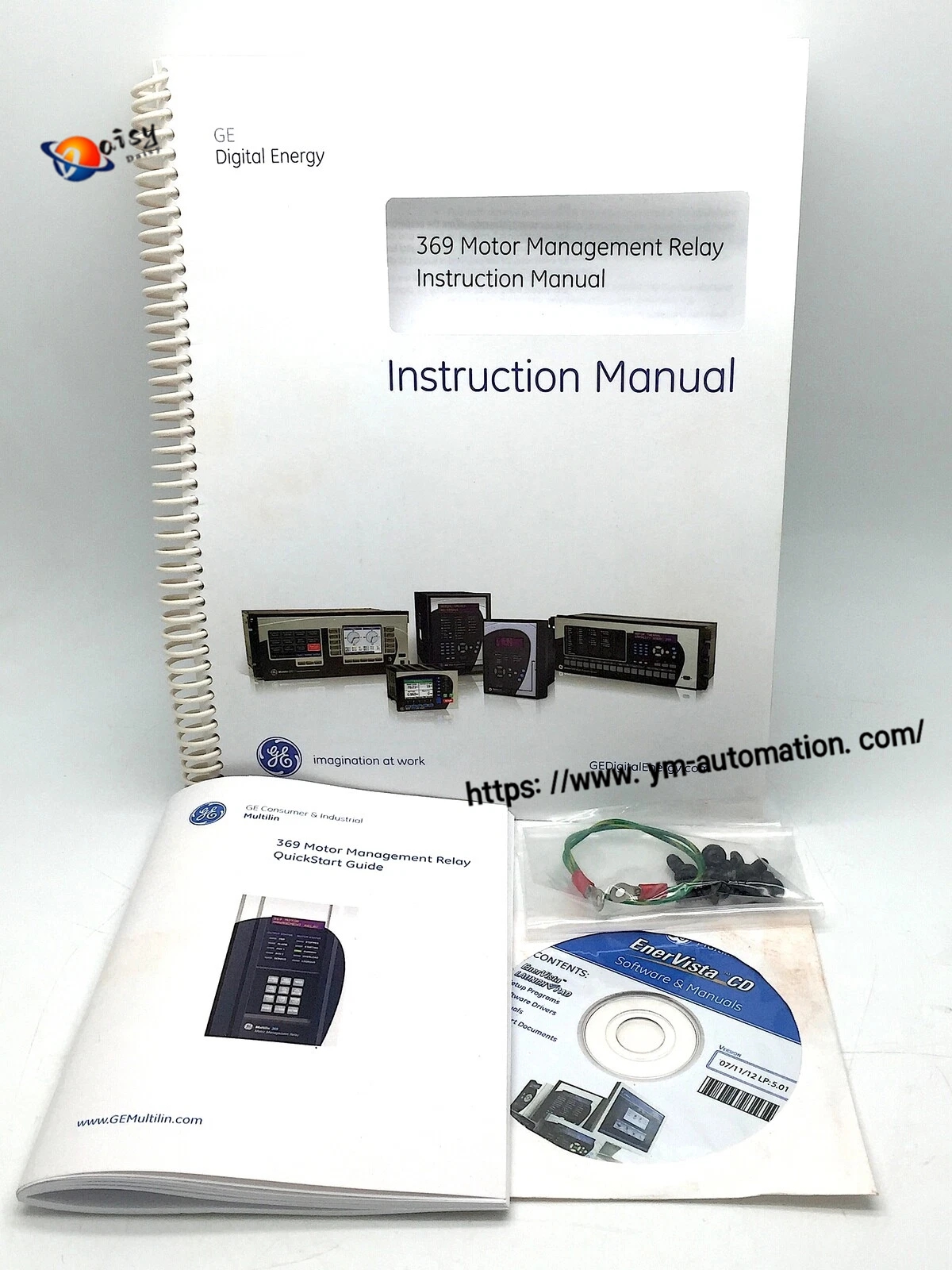

Brand:GE

Product ID:

Place of Origin:

Warranty: 365 days

Goods status: new/used

Mail: 3598571032@qq.com

Phone/Wechat/Whatsapp:+86 15339539190

If the product model is inconsistent with the displayed image, the model shall prevail. Please contact us for specific product images, and we will arrange for photos to be taken and confirmed in the warehouse

We have 16 shared warehouses worldwide, so sometimes it may take several hours to accurately return to you. We apologize for any inconvenience caused. Of course, we will respond to your concerns as soon as possible.

Main products:

Covering globally renowned brands:

Bently Nevada, Triconex, Woodward, Foxboro, Westinghouse, Reliance, Schneider Modicon, ABB, Allen-Bradley, Motorola, GE Fanuc, Yaskawa, Bosch Rexroth, ACSO, Yokogawa, Rexroth, NI, ICS Triplex, Kollmorgen, Mitsubishi, MOOG, Emerson, B&R, Alstom, EPRO, HIMA, Honeywell, Prosoft, AMAT, Siemens, etc.

Product categories include: DCS system accessories, robot system spare parts, large servo system spare parts, etc., widely used in power, chemical, metallurgy, intelligent manufacturing and other fields.

+86 15339539190