Brand:ABB

Product ID:

Place of Origin:

Warranty: 365 days

Goods status: new/used

Mail: 3598571032@qq.com

Phone/Wechat/Whatsapp:+86 15339539190

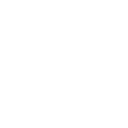

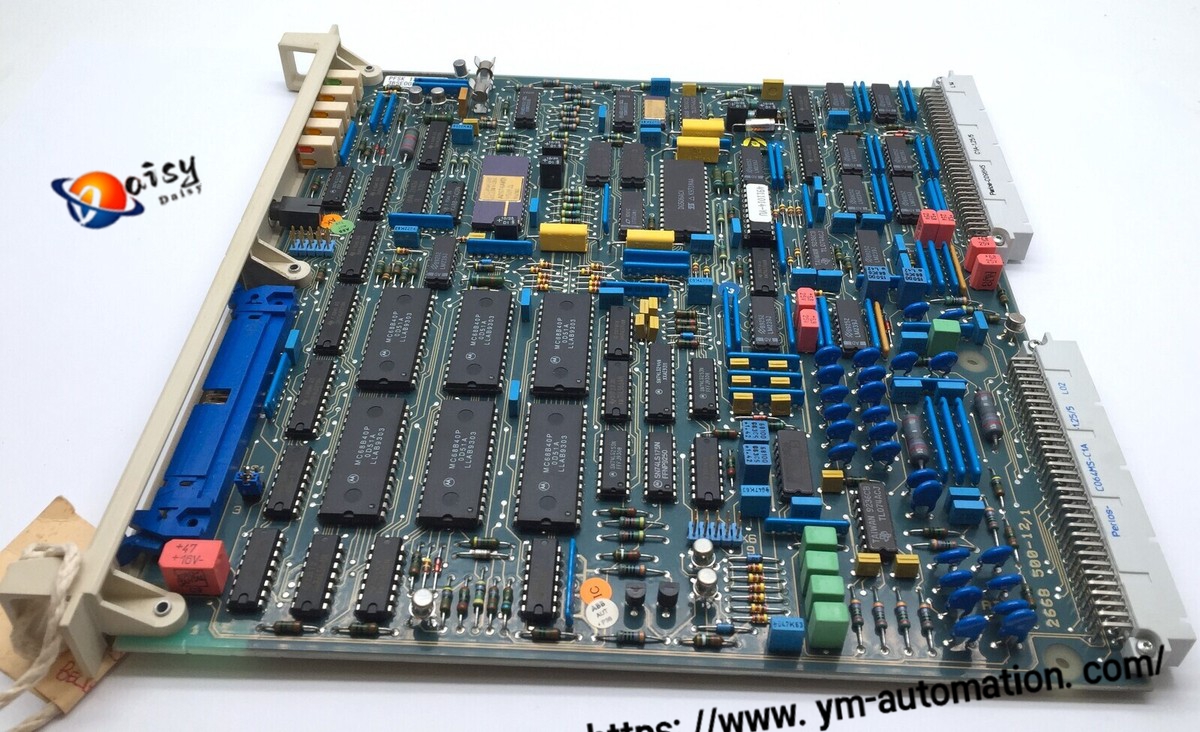

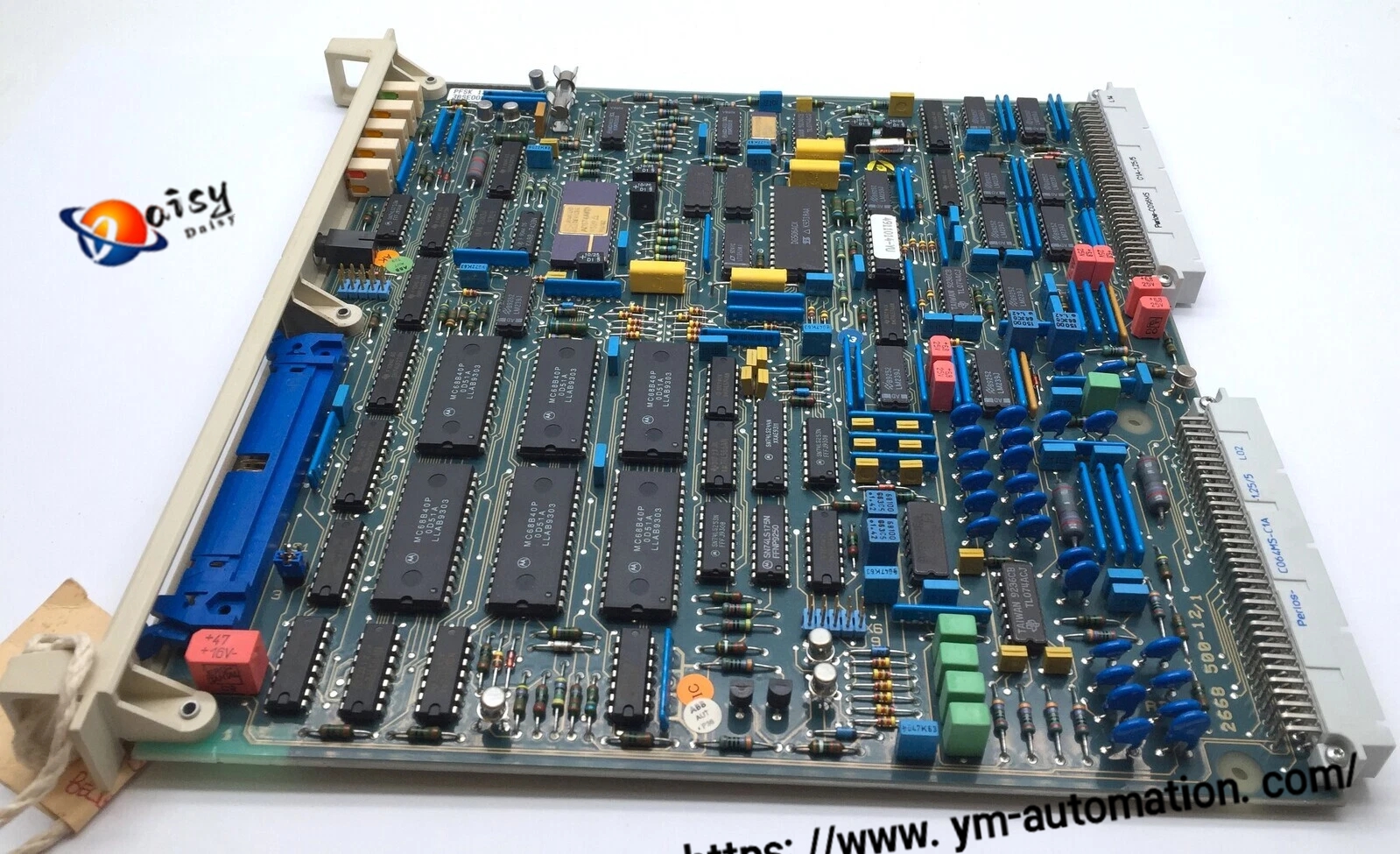

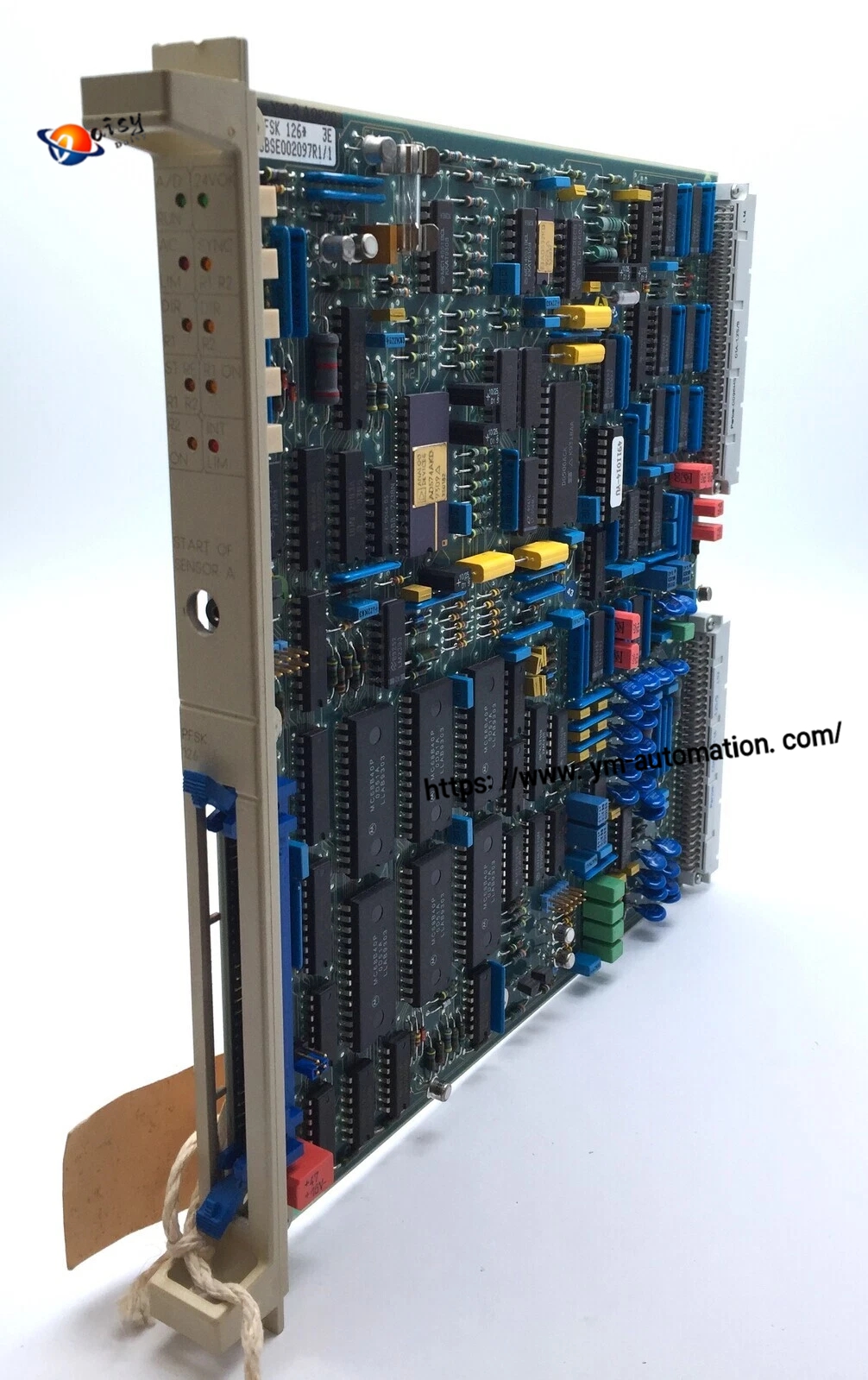

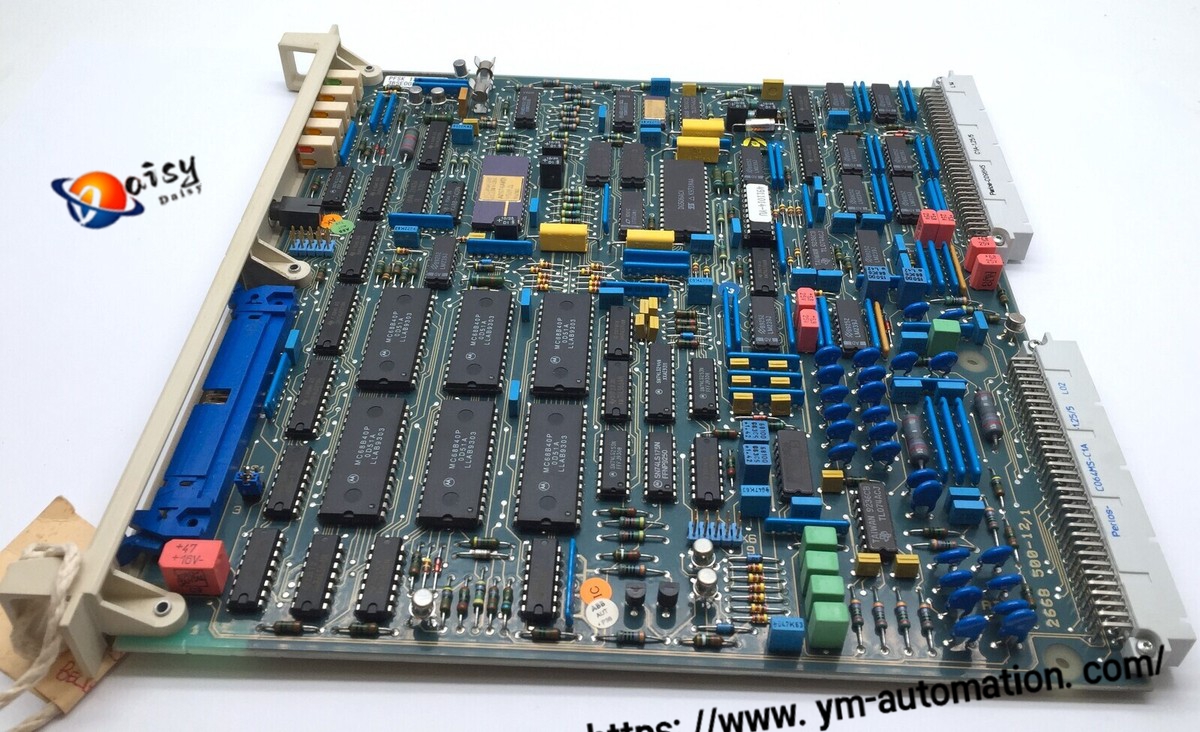

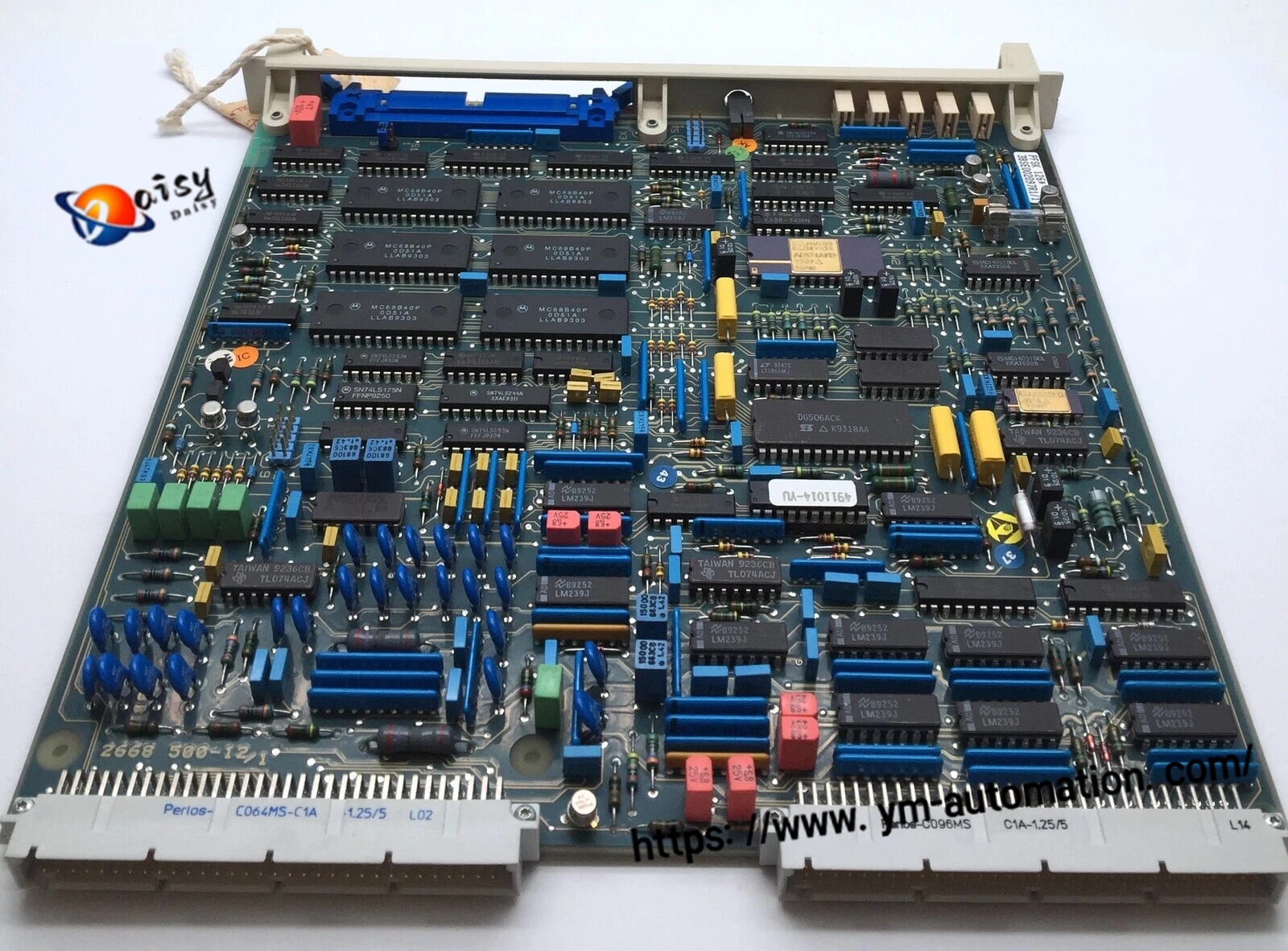

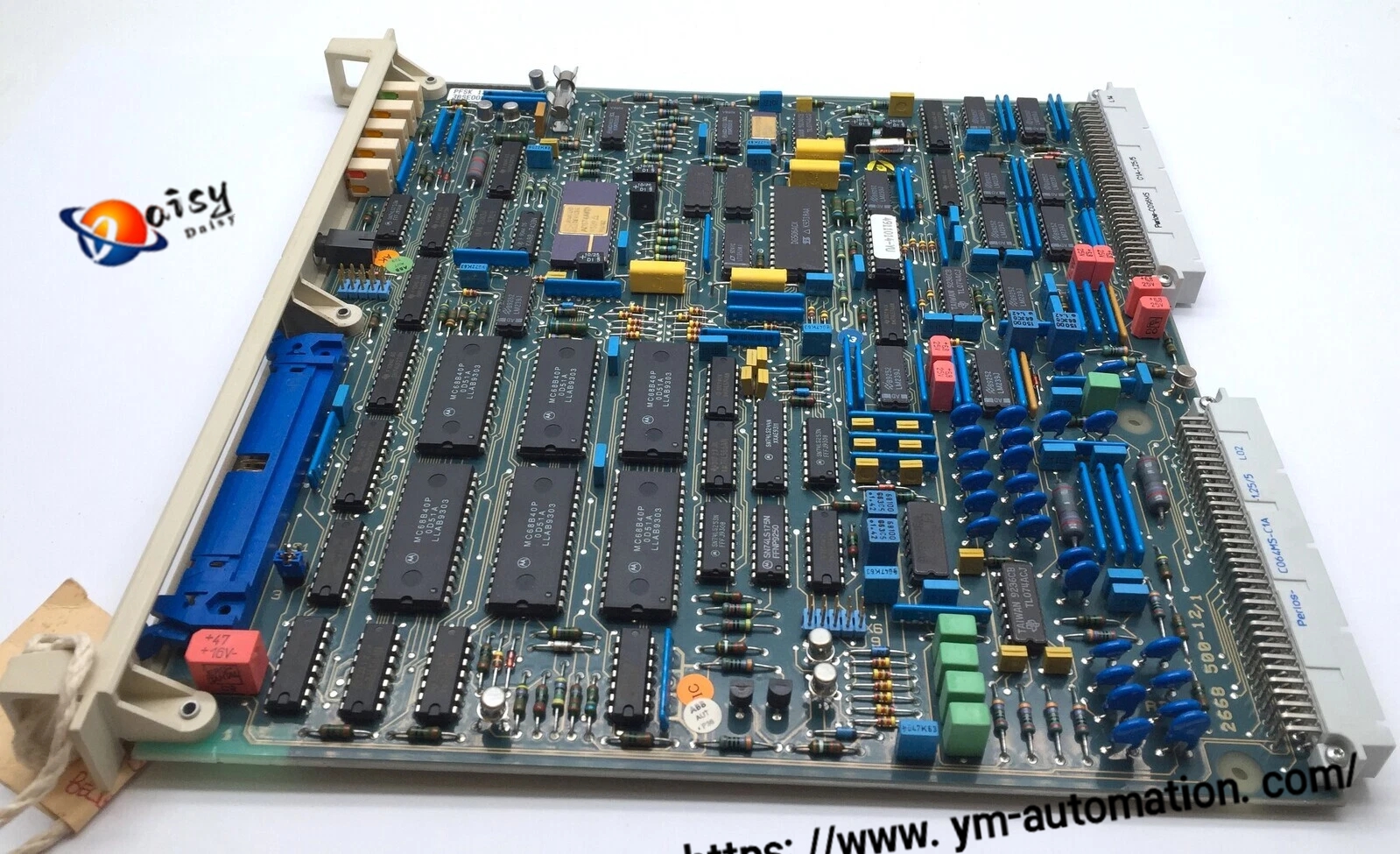

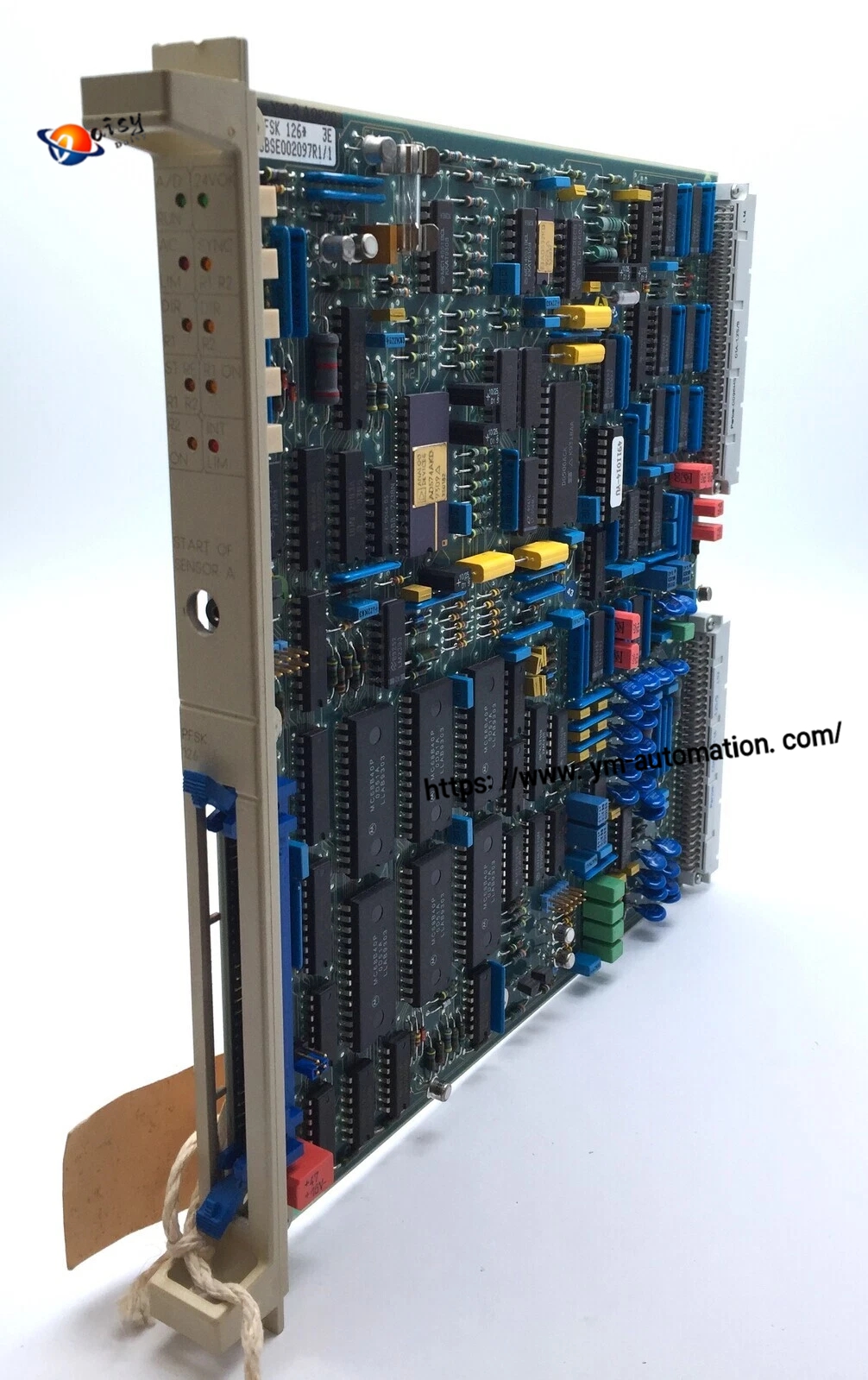

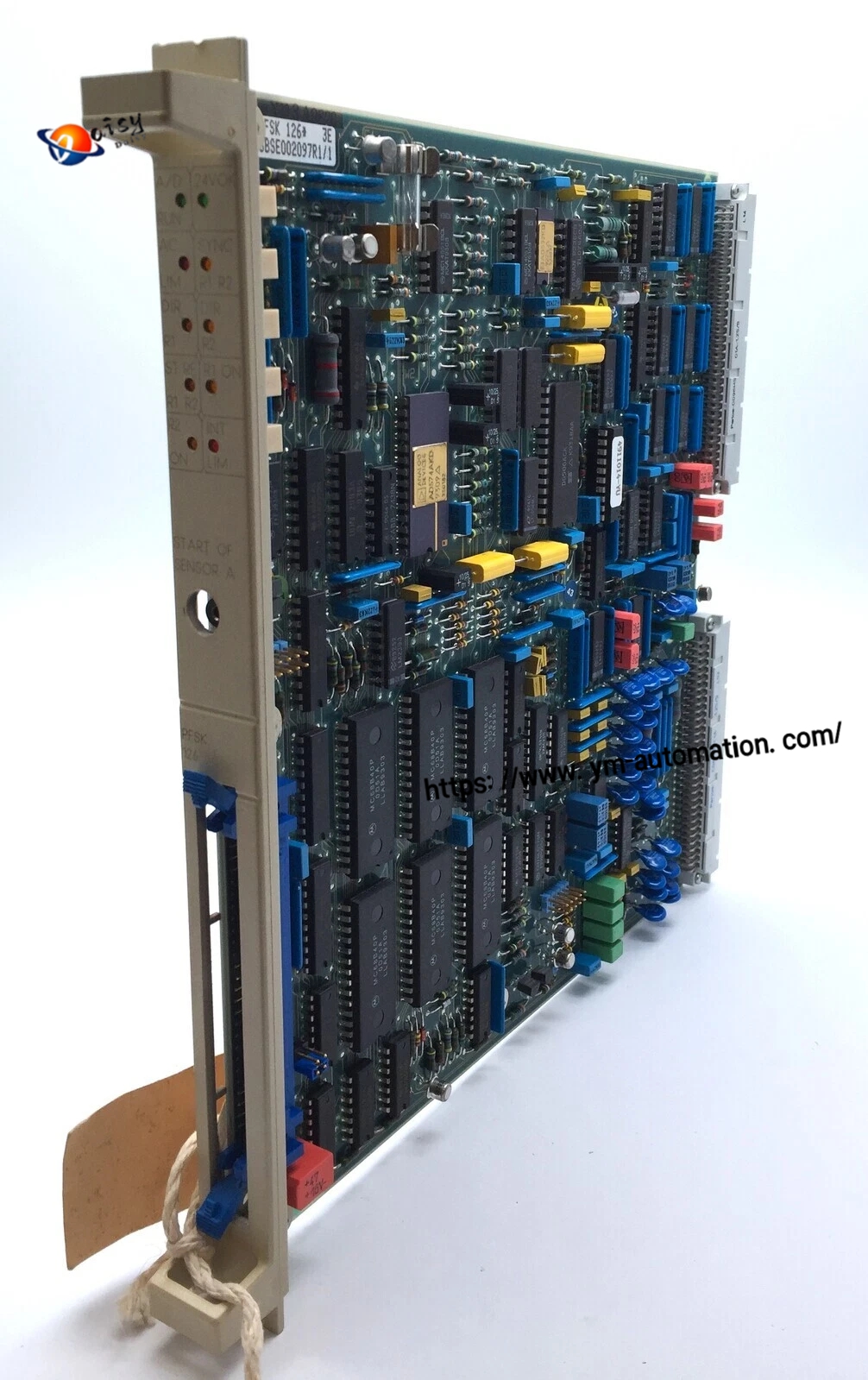

Basic Attributes: Model PFSK126, order number 3BSE002097R1, a digital input/output hybrid module.

Power Supply: Operating voltage 24 VDC (typical value); power consumption max. 3 W (approx. 1.5 W under no-load condition).

Input Channels: 16 digital input (DI) channels, compatible with PNP/NPN (switchable via hardware); input voltage range 18-30 VDC; max. current per channel 10 mA; response time ≤ 1 ms (typical value).

Output Channels: 8 digital output (DO) channels, relay output (normally open contacts); rated contact capacity 250 VAC/2 A or 30 VDC/2 A; equipped with self-recovering short-circuit protection.

Environmental Adaptability: Operating temperature -5 °C ~ +60 °C; storage temperature -40 °C ~ +85 °C; relative humidity 10%-95% (non-condensing, no corrosive gas); protection rating IP20 (must be installed in a control cabinet).

Communication & Installation: Supports RS-485 backplane bus of the ABB Advant OCS system; each channel is equipped with an LED status indicator (for input/output/fault); 35 mm DIN rail mounting (compliant with EN 60715 standard).

Certifications: Compliant with IEC 61010-1 (industrial control safety standard) and EN 61326-1 (industrial EMC anti-interference standard).

DI Signal Acquisition: The 16 DI channels connect to on-site sensors (e.g., limit switches, photoelectric sensors). When the on-site equipment outputs a 24 VDC signal or the contact is closed, the photoelectric coupler inside the DI channel is activated to convert the analog signal into a digital signal ("1" for signal present, "0" for no signal). After anti-interference filtering, the signal is transmitted to the Advant OCS controller via the RS-485 bus to complete the upload of on-site status.

DO Signal Execution: The controller sends commands based on preset logic ("1" for activation, "0" for deactivation). The module then drives the relay coil of the DO channel to energize/de-energize, closing/opening the normally open contacts. This outputs 24 VDC/250 VAC control signals to actuators (e.g., solenoid valves, alarm lights) to implement the issuance of action commands.

Fault Diagnosis: It monitors power supply (alarm triggered for abnormal power supply), channels (corresponding LED flashes in case of short circuit/overload), and communication (yellow LED stays on if bus connection is interrupted) in real time. Fault information is synchronized to the controller for easy troubleshooting.

Process Industry: Petrochemical industry (status monitoring and control of pumps/valves in refining units), water treatment (start/stop of aeration fans/sludge pumps in sewage plants), and auxiliary systems of thermal power plants (deviation monitoring of coal-conveying belts).

Discrete Manufacturing: Automotive parts assembly lines (acquisition of robot in-place signals, control of equipment start/stop) and safety interlocking of machine tools/injection molding machines (monitoring of safety door signals and control of main power supply).

Infrastructure: Port cranes (acquisition of limit switch signals, control of brakes) and auxiliary systems of renewable energy (overcurrent monitoring of PV combiner boxes, access interlocking of wind turbine towers).

Legacy System Upgrading: Used for capacity expansion or faulty module replacement of existing ABB Advant OCS systems, eliminating the need to replace controllers and reducing transformation costs.

Main products:

Covering globally renowned brands:

Bently Nevada, Triconex, Woodward, Foxboro, Westinghouse, Reliance, Schneider Modicon, ABB, Allen-Bradley, Motorola, GE Fanuc, Yaskawa, Bosch Rexroth, ACSO, Yokogawa, Rexroth, NI, ICS Triplex, Kollmorgen, Mitsubishi, MOOG, Emerson, B&R, Alstom, EPRO, HIMA, Honeywell, Prosoft, AMAT, Siemens, etc.

Product categories include: DCS system accessories, robot system spare parts, large servo system spare parts, etc., widely used in power, chemical, metallurgy, intelligent manufacturing and other fields.

+86 15339539190